Dry Etching

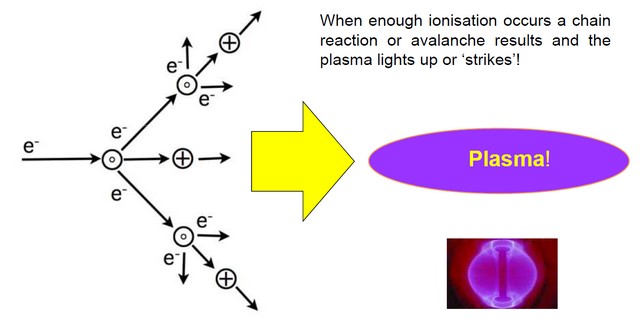

Plasma is "the fourth state of matter", and consists of a combination of UV-visible radiation and unstable gaseous radicals and ions. In a laboratory environment it can be created in a controlled way using various methods. Most of them require high vacuum in order to control the gaseous environment. Different feed gases show different reactivity towards different solids. The Nanolab is equipped with plasma systems that employ different feed gases. The most common are oxygen and argon which are used for cleaning and "sputtering" of silicon and silicon dioxide. Exotic gases such as boron trichloride and sulfur hexafluoride are also used for various special applications such as deep etching of nano-sized trenches in Si or etching of tungsten, molybdenum etc.

Plasma can be created in different ways:

- Radio frequency (RF) plasma - created by applying an RF AC-bias between the plates of a capacitor. The substrate piece is placed on one of the capacitor plates.

- Inductively coupled plasma (ICP) - created remotely by an induction coil and fed onto the sample. High density and low energy of ions/radicals. It is combined with RF-plasma in the same tool to provide ideal conditions for a wide range of etching needs

- DC plasma - similar to RF plasma, but done with DC bias. Only works on conductive substrates (not available in the Nanolab)

The plasma tools in the Nanolab are provided by Oxford. Their website is a very good resource to learn about plasma processes, and which should be used for your application.

While being expensive in terms of capital investment and running costs, dry etching is relatively "environmentally friendly" and fast, avoiding the need for use of toxic or harmful chemicals. Depending on the process used, it can also provide high precision in fabrication of nanostructures with steep side-walls.

Wikipedia provides a concise summary of wet and dry etching techniques for micro- and nanofabrication here .